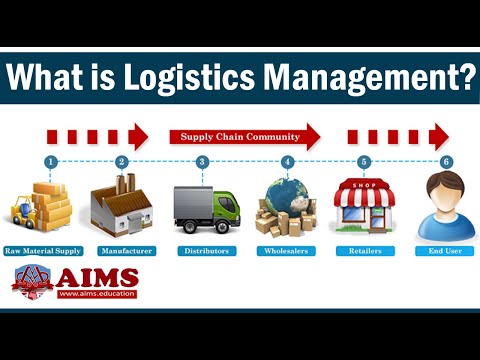

Logistics Meaning and Definition

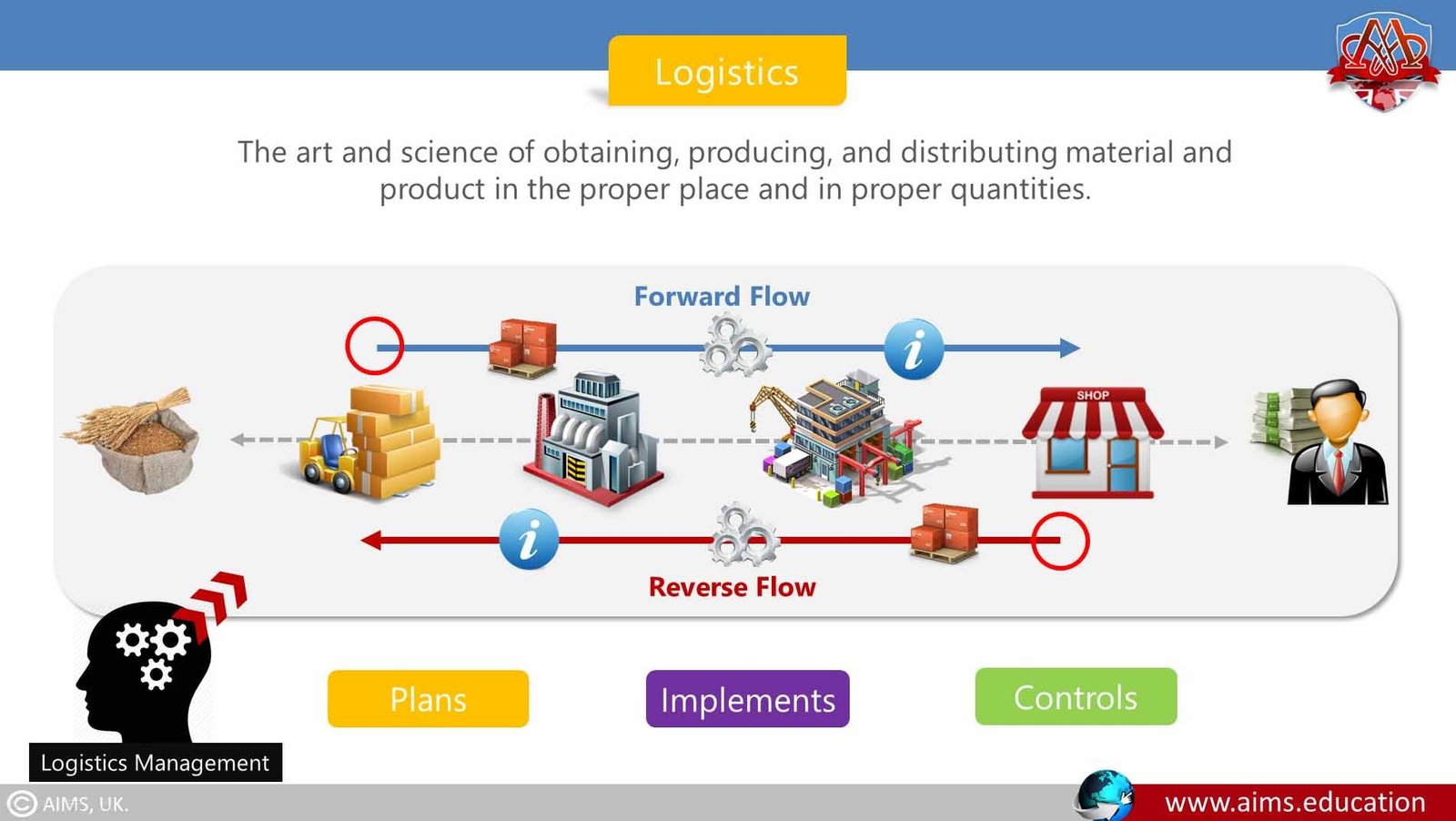

Logistics, in its broadest sense, refers to the detailed organization and implementation of a complex operation. In a more specific context, the logistics meaning encompasses the movement of goods, ensuring that the right product reaches the right customer at the right time and place. Essentially, when we ask “what is logistics?” we’re inquiring about the processes involved in getting a product or service from the supplier to the customer in the most efficient and cost-effective manner. “Logistics Management” is a subset of logistics that includes transportation, warehousing, inventory management, material handling, and packaging, all aimed at achieving efficient distribution.

Programs

5 Key Areas in Logistics Management

Logistics management is a complex network, which involves numerous key areas that contribute to its smooth operation. These areas are integral to achieving an efficient and successful operation.

1. Inventory Management

At the heart of this network is Inventory Management, which refers to the process of ordering, storing, and using a company’s inventory. It’s about having the right product in the right quantity, in the right place, at the right time. For instance, a company like Amazon utilizes advanced inventory management systems to keep track of millions of products in its warehouses globally.

2. Transportation Management

It is another crucial aspect. It involves the planning, execution, and optimization of the physical movement of goods, ensuring they are transported from the point of origin to the destination efficiently and effectively. FedEx, for example, utilizes sophisticated transportation management systems to orchestrate the delivery of packages globally.

3. Warehousing

Warehousing plays an integral role in storing products safely and securely until they are needed for distribution, thus serving as a critical link in the supply chain. IKEA, the globally recognized furniture retailer, maintains large warehouses to store its wide range of products until they are dispatched to various retail outlets.

4. Order Fulfillment

Order Fulfillment is the process that ensures that customer orders are processed and delivered most efficiently, maintaining customer satisfaction and loyalty. Zappos, an online shoe retailer, exemplifies this with its fast and efficient order processing and delivery system, offering free shipping and returns to enhance customer satisfaction.

5. Demand Planning

Demand Planning is about forecasting the demand for products accurately to avoid overstocking or understocking, ensuring that the right product quantities are available at the right time to meet customer needs. Apple Inc. is known for its effective demand-planning processes, which allow it to launch new products seamlessly worldwide.

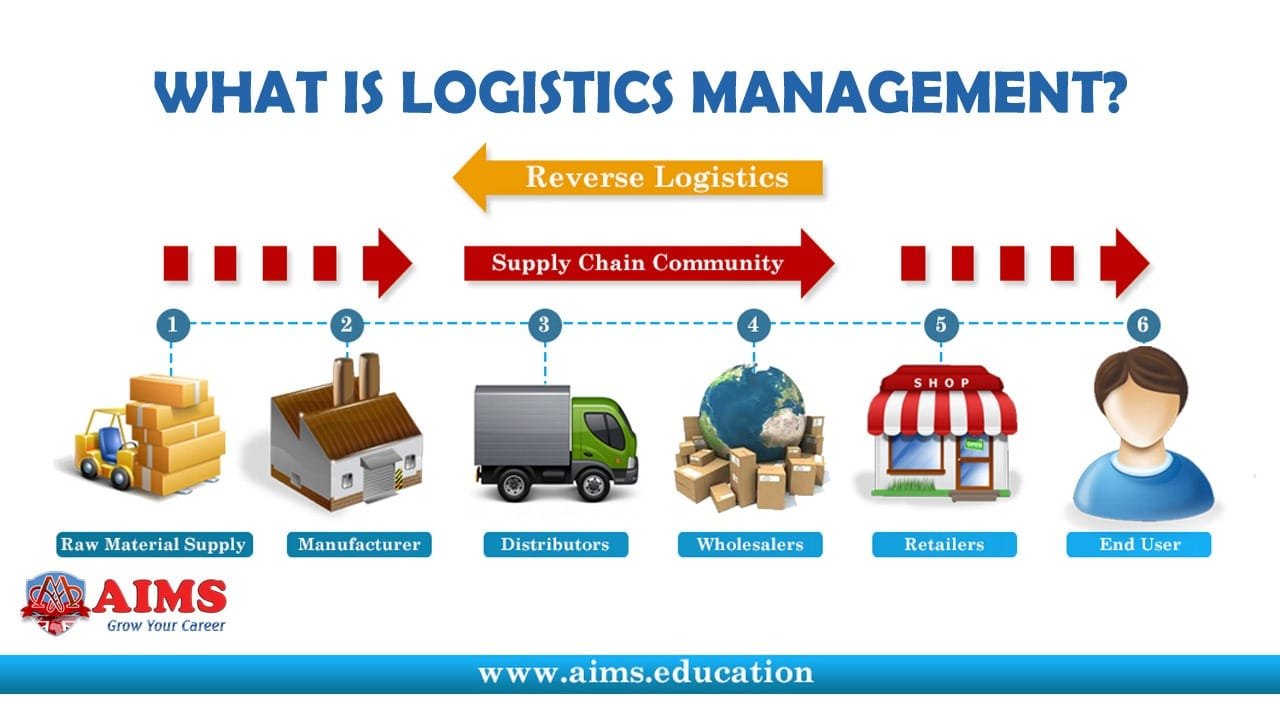

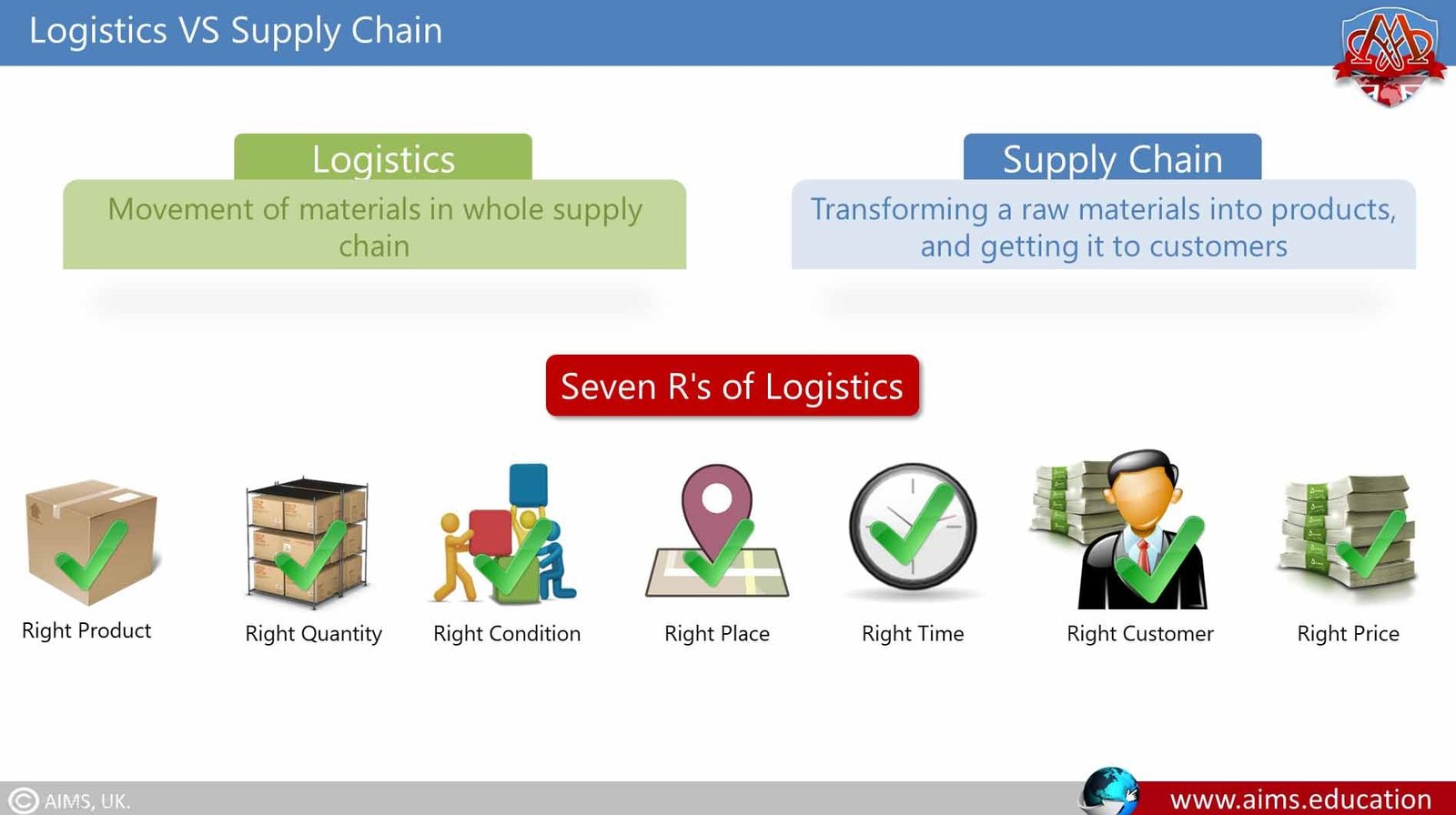

Logistics Management VS Supply Chain Management

While logistics management and supply chain management are often used interchangeably, they represent distinct aspects of a company’s operations. Here are some key differences:

1. Definition

Logistics management is a subset of supply chain management (SCM). It focuses on the planning, implementation, and control of the efficient flow and storage of goods, services, and related information from the point of origin to the point of consumption. On the other hand, supply chain management is a broader concept that encompasses all activities involved in sourcing, procurement, conversion, and logistics management. It also includes coordination and collaboration with channel partners, which could be suppliers, intermediaries, third-party service providers, or customers.

2. Scope

Logistics management is concerned with inbound and outbound transportation, warehousing, inventory management, and related activities. Supply chain management considers end-to-end processes, looking at every element from raw material sourcing to final product delivery, including customer service and feedback.

3. Roles and Responsibilities

Logistics managers mainly deal with transportation vendors, warehouse operations, and inventory control. In contrast, supply chain managers work with procurement, production, logistics, and sales, overseeing all steps of the product life cycle.

4. Goals

The goal of logistics management is to ensure timely and cost-effective delivery of goods from the point of origin to the point of consumption. Supply chain management aims at creating value, building a competitive infrastructure, synchronizing supply with demand, and measuring performance globally.

Examples of Logistics Management

1. Prime Delivery

Amazon’s Prime Delivery is an excellent example of effective logistics management. They have mastered the art of quick and efficient delivery, providing their customers with a seamless shopping experience. The company has a vast, well-organized network that allows for same-day or even two-hour delivery in certain areas.

2. Cross-Docking

Walmart employs a logistic strategy known as cross-docking. With this method, products from suppliers are directly distributed to stores, reducing the need for storage space and hence, minimizing storage costs. This efficient logistics management strategy enables Walmart to keep low prices for their customers.

3. Delivery

Domino’s Pizza is renowned for its effective management, specifically its impressive delivery system. The company’s logistics infrastructure allows it to deliver hot pizzas to customers in a very short time, a key factor in its success.

4. Fast Fashion Model

Zara, a leading fashion retailer, utilizes an agile and efficient logistics management system. Their model supports the quick turnaround of new fashion trends, with new designs reaching stores within weeks. This rapid response to market demand is enabled by a streamlined supply chain and effective logistics management.

Four Types of Logistics

Logistics is a broad field, encompassing a variety of operations that ensure the smooth flow of goods and services from the point of origin to the point of consumption. These operations can be broadly categorized into the following four types:

1. Inbound Logistics

This type involves the movement of raw materials and goods from suppliers to a company’s production facilities. It focuses on the efficient and timely transportation, storage, and delivery of goods, which is crucial for maintaining production schedules.

2. Outbound Logistics

It pertains to the movement of finished products from a company’s production site to the end consumer. This includes warehousing, packaging, transportation, and distribution of goods.

3. Third-Party Logistics (3PL)

This involves outsourcing logistic functions to third-party logistics providers. These providers offer a wide range of services, including transportation, warehousing, and inventory management, allowing companies to focus on their core business functions.

4. Reverse Logistics

Reverse logistics refers to the process of moving products from the end customer back to the producer, mainly for disposal or recycling. It includes activities such as returns, warranties, and recycling programs.

Each of these types plays a critical role in a company’s supply chain, demonstrating the diverse logistics meaning in various contexts. Understanding these facets helps define logistics management and its importance to a company’s success.

Goals and Objectives of Logistics

At the pinnacle, the goal of logistics management echoes that of the supply chain – to fulfill customer requirements. Most experts concur on several objectives:

- React swiftly to market changes or modifications in customer orders.

- Curb variances in logistics services.

- Lower inventory levels to cut down on costs.

- Enhance product movement by consolidating shipments. Uphold high-quality standards and perpetually strive for improvement.

- Back the entire product life cycle along with the reverse supply chain.

Importance of Logistics Management

Logistics plays a crucial role in the operational efficiency and success of any business. It involves the integration of information flow, material handling, production, packaging, transportation, warehousing, security, and much more. Here are five key areas where it is paramount:

1. Customer Satisfaction

A well-managed logistical system ensures timely deliveries, which results in increased customer satisfaction. This can lead to repeat orders and long-term customer loyalty. For instance, Domino’s Pizza’s effective logistics management contributes significantly to its promise of prompt pizza delivery.

2. Cost Management

Efficient logistics can help in reducing operating costs. Proper routing, load optimization, and mode selection can result in substantial savings in both short and long-term operations.

3. Competitive Advantage

A company with superior logistics can often provide better service than its competitors, thereby gaining a competitive edge. This is evident in the case of clothing retailer Zara, whose unique model allows rapid response to changing fashion trends.

4. Scalability

As businesses grow and operations expand, a well-planned system can help manage the increased complexity and volume. Apple’s robust logistics are a prime example, enabling it to coordinate with hundreds of suppliers worldwide.

5. Sustainability

Effective logistics management can contribute to sustainability by reducing wastage, optimizing routes for lower fuel consumption, and managing returns more efficiently. This aspect is becoming increasingly important as businesses strive to reduce their environmental impact.

Logistics Strategies

Logistics strategies primarily depend on five key factors:

Factor # 1: Coordinating Functions

Successful logistics is about seamlessly coordinating various functions such as transportation management, warehousing, and packaging to create maximum value for the customer. Each of these logistical operations adds value to the final product by ensuring that it reaches the consumer in optimal condition and within set timelines. For instance, effective transportation management reduces delivery times while adept warehousing preserves the quality of goods.

Factor # 2: Integrating the Supply Chain

Logistics is not a standalone function; it is an integral part of the entire supply chain. Therefore, integrating the supply chain is a crucial aspect of defining logistics. It means that all components of the supply chain – from raw material acquisition, production, and delivery to end consumer – need to work in harmony. This integration of logistics reduces bottlenecks, improves efficiency, and enhances customer satisfaction.

When defining it within the context of integrating the supply chain, several key steps must be prioritized, including:

A. LOCATE IN THE RIGHT COUNTRIES

The geographical location of your vendors, manufacturing units, and customer base largely influence your logistics effectiveness. The decision should consider factors like manufacturing costs, labor laws, environmental regulations, and market accessibility.

B. DEVELOP AN EFFECTIVE IMPORT-EXPORT STRATEGY

An efficient import-export strategy is integral to smooth logistics. This includes understanding global trade agreements, customs regulations, and tariffs. Having a robust strategy can save time, prevent legal issues, and reduce costs.

C. SELECT WAREHOUSE LOCATION

The location of the warehouse is another crucial factor in logistics management. It should ideally be close to suppliers, production facilities, and major transportation routes to minimize transit time and cost.

D. SELECT TRANSPORTATION MODES AND CARRIERS

The choice of transportation—air, water, rail, or road—depends on factors like the nature of the product, delivery speed, and budget. Selecting reliable carriers who adhere to timelines and ensure safe delivery of goods is equally important.

E. SELECT THE RIGHT NUMBER OF PARTNERS

Balancing the number of partners in the supply chain is critical. Too many partners can complicate logistics, while too few can lead to dependency risks. Careful selection and management of partners contribute to a robust and efficient supply chain.

F. DEVELOP START-OF-THE-ART INFORMATION SYSTEMS

Modern logistics relies heavily on advanced information systems for order tracking, inventory management, and demand forecasting. These systems promote transparency, improve coordination, and enable data-driven decision-making.

Factor # 3: Substituting Information for Inventory

Logistics management is a multifaceted process, and one of its fundamental aspects is the efficient handling of information. The saying “Information is the new inventory” rings true in modern logistics, as many traditional inventory management practices can now be substituted or enhanced through better use of information. Here’s how:

A. IMPROVE COMMUNICATIONS

By improving communication channels within the company and with external partners, a company can ensure that all parties have accurate and up-to-date information about the inventory. This can help in avoiding overstocking or understocking situations, thereby leading to a more efficient inventory management system.

B. COLLABORATE WITH SUPPLIERS

Close collaboration with suppliers can provide a steady flow of timely and accurate information about the incoming inventory. This can help in better predicting demand, scheduling deliveries, and reducing lead times, effectively lowering the need for maintaining large amounts of inventory.

C. TRACK INVENTORY PRECISELY

Advanced tracking systems like RFID and barcode technology can provide real-time information about the inventory at hand. This precise tracking enables quicker response to changes in demand, reducing the need for safety stock and improving the overall efficiency of the inventory management process.

D. KEEP INVENTORY IN TRANSIT

By keeping inventory in transit instead of in storage, companies can effectively reduce the amount of physical inventory they need to hold. This “Just-In-Time” strategy requires sophisticated tracking and information systems but can significantly reduce storage costs and lead times when done correctly.

Factor # 4: Reducing Supply Chain Partners

While a large network of partners might seem beneficial, it can often lead to complexity and inefficiencies in logistics management. Therefore, reducing the number of supply chain partners to an effective minimum is vital. It simplifies coordination, improves transparency, and enhances the overall control over the supply chain.

Factor # 5: Pooling Risks

Finally, pooling risks is an essential strategy. It means sharing risks with partners across the supply chain to minimize the impact of unforeseen circumstances. This strategy ensures that the burden of disruptions, whether caused by demand variability or supply issues, does not fall on a single entity, thus fortifying the resilience of the system.

Transportation Costing in Logistics

It refers to the cost incurred to move goods from the supplier to the customer. This includes the expense of fuel, driver salaries, toll charges, maintenance of vehicles, insurance, and regulatory fees. Transportation costs directly impact the price of goods and services, making it a significant factor in logistics.

Minimizing logistics costs is key to improving the profitability of a business. Some strategies to achieve this include:

- Optimization of routes: Using software or algorithms to determine the most efficient routes can significantly reduce fuel consumption and travel time.

- Consolidation of loads: Combining smaller shipments into a single larger shipment can lead to cost savings through reduced transportation frequency.

- Regular maintenance of equipment: Regularly servicing and maintaining transportation equipment can help avoid unexpected repair costs and ensure operational efficiency.

- Investment in technology: Advanced technologies, such as automation and real-time tracking systems, can enhance operational efficiency and reduce wastage.

- Building strong relationships with partners: Negotiating better rates with transportation vendors and long-term contracts can lead to significant savings.

- Performance tracking and continual improvement: Regularly analyzing performance metrics and identifying areas for improvement can help reduce costs over time.

What is the Value Proposition in Logistics?

A value proposition in logistics is the unique combination of services promised by a logistics provider to its clients. The value proposition aims to convince potential customers that the services offered surpass those of competing providers in terms of quality, cost, or a combination of both. Essentially, it’s the answer to the question, “Why should a customer choose us for their logistics needs?”

Importance of Certification and Education in Logistics Management

A robust foundation in the intricate world of logistics often begins with formal educational qualifications. Courses such as an MBA or diploma in logistics offer an in-depth understanding of the field and equip students with the necessary skills to handle logistical challenges. An MBA in logistics management provides insights into supply chain management, operational methods, and strategic aspects of logistics. For those aiming to delve deeper into research or high-level strategic roles, a doctorate in logistics management can be a viable option. Additionally, obtaining a logistics certification can validate an individual’s expertise and open up doors to better career opportunities.

Last Word

In conclusion, logistics management serves as the backbone of any business dealing with the production and delivery of goods. The logistics definition encapsulates a broad range of operations, from inventory management and warehousing to transportation and customer service. The logistics meaning is deeply intertwined with cost-efficiency, customer satisfaction, and overall business success. Whether it is FedEx with its promise of speed and reliability or Amazon with its technologically driven flexible delivery options, each company’s strategy reflects its unique value proposition. Understanding and mastering the intricacies of logistics management is, therefore, a critical factor for businesses aiming to gain a competitive edge in today’s fast-paced, demand-driven market.