What is Supply Chain Analysis?

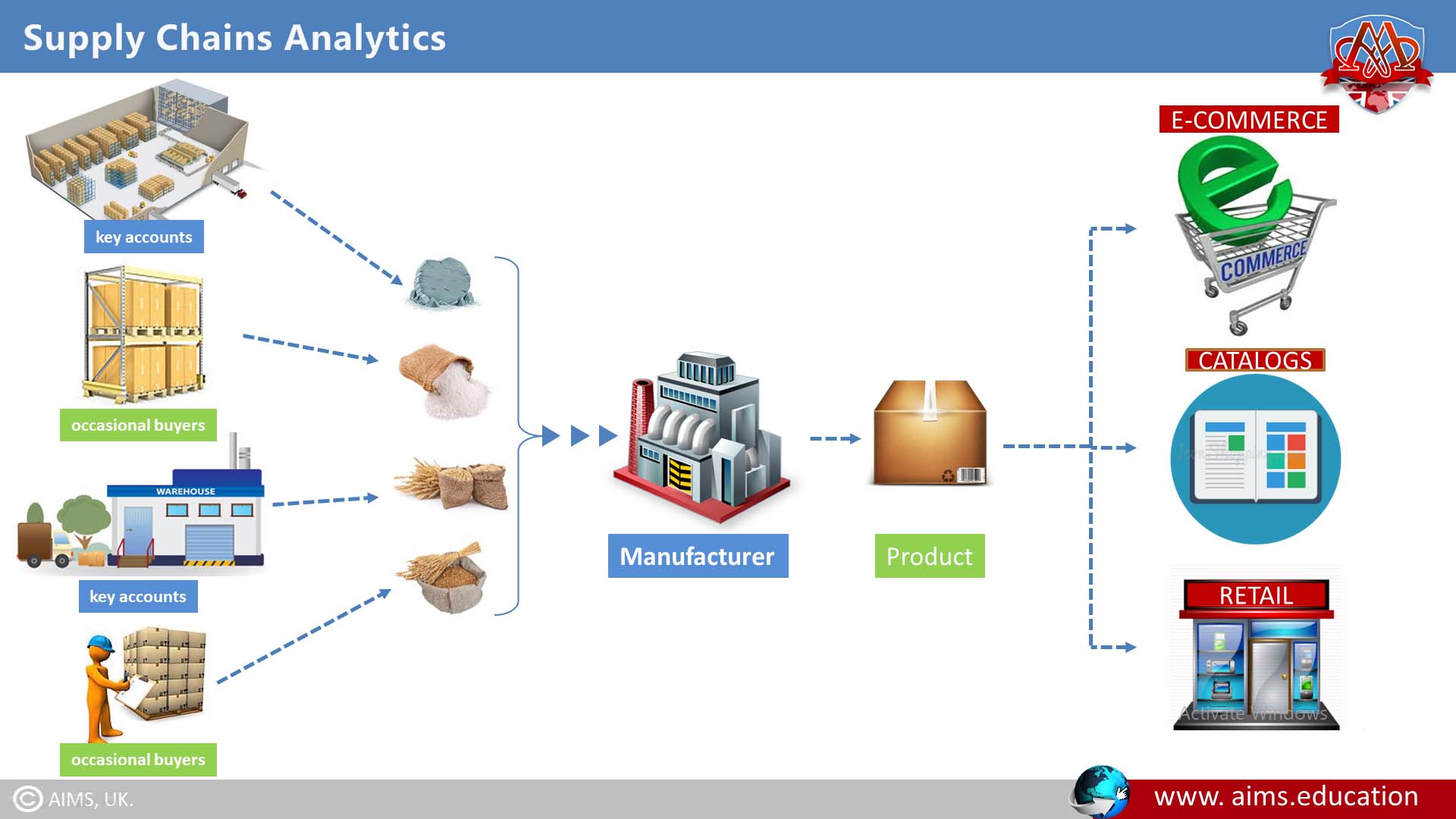

The economies and trade regulations change constantly, which affects the flow of goods. However, it can be handled with the help of SCM analysis. Supply chain analysis is a process of gathering data from different parts of the supply chain, organizing it, and analyzing it for understanding the future needs of your business. By implementing supply chain planning techniques and models, businesses can gather and analyze all the historical and recent data of their business. It helps them better predict the future demands of their business. And once it is understood, there are more chances for businesses to grow at a faster pace.

Why There is a Need for Supply Chain Analysis?

These days, supply chains evolved in a great manner, as goods are being sent all over the globe from various locations. As a business manager, it is important to know how to properly the supply chain analysis is done. So you can adjust and change it according to the needs of your business. While a supply chain may appear in an ideal shape at first, it may turn out to be not that effective when it starts working. This is why you need to make an efficient chain analysis, using the right supply chain analysis tools, to spot any leaks or problems before they trigger any issues for your company. You may also need to perform periodic analysis.

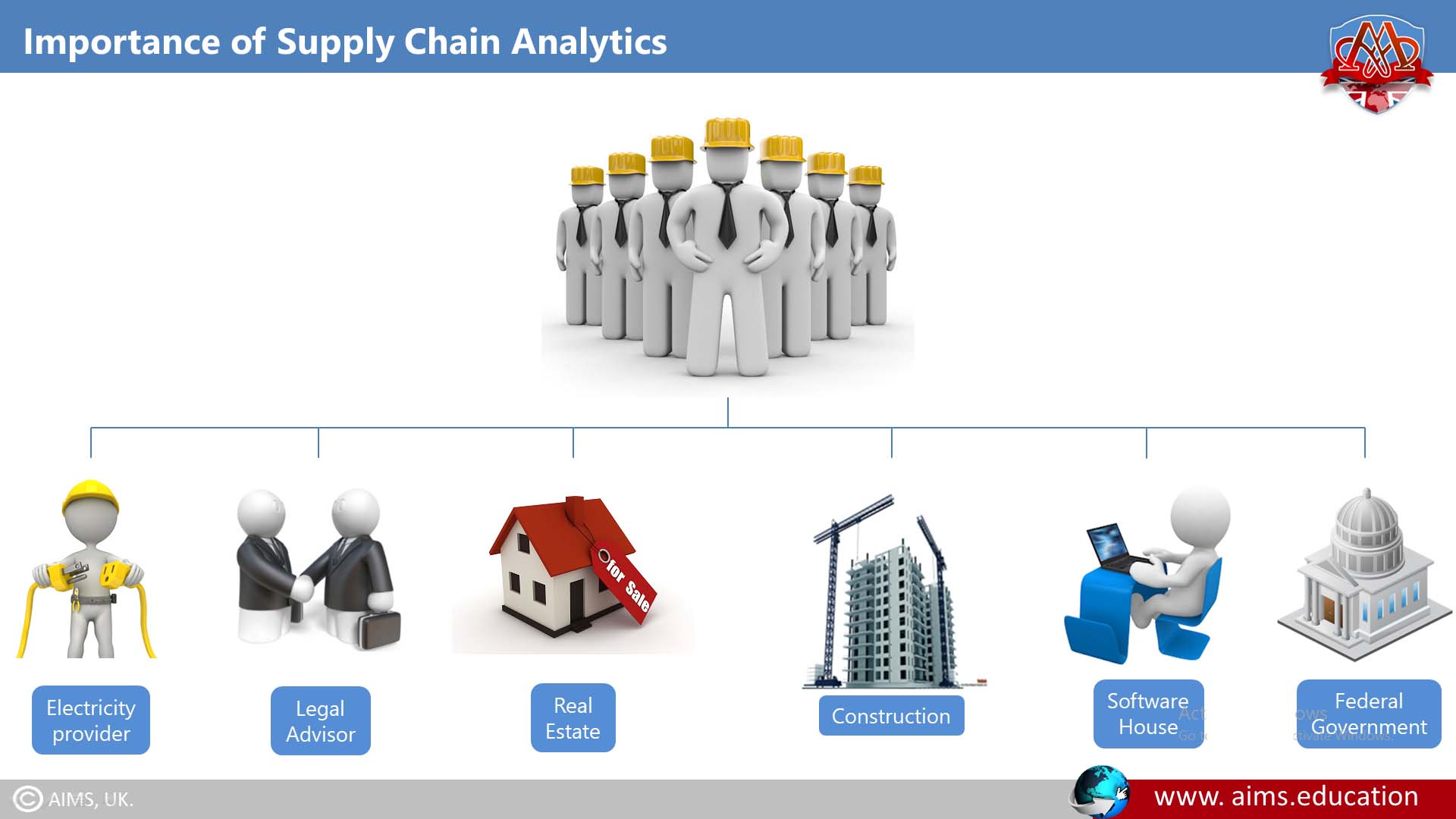

Supply chain analysis is practically a tool you can use to check out the efficiency of your supply chain and to spot any regional business opportunities. Every enterprise and business is a link of a greater supply chain. This kind of analysis will allow you to see if there are any chances for you to grow your business furthermore.

Key Note!

What is the Importance of SCM Analysis?

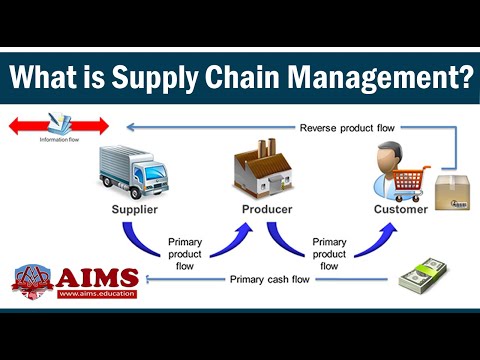

A supply chain is a network of companies that produce, distribute, and sell products. Supply chain management aims to bring together the various players involved in a supply chain in order to deliver these products to customers as efficiently and effectively as possible. This means that supply chain managers must monitor their supply chains closely in order to identify any potential problems or inefficiencies. A supply chain analytics strategy is the way that your organization collects and analyzes data in order to make better decisions about the supply chain and improve the overall performance of your business. SC Analytics can be used to identify and solve problems across the entire supply chain, from procurement to transportation, inventory management, and customer service.

Supply chain management analysis is covered in more detail in the CSLP (logistics courses online) and CSCE (supply chain management courses online). These programs are offered by AIMS, through a flexible and self-paced interactive learning system.

How to Analyze a Supply Chain?

Supply chain data analysis is the gathering and analysis of all the data produced by the various arms of the supply chain.

- It helps you dig deeper into the supply chain data to examine the efficiency gaps and improve the operational, financial, and managerial aspects of the supply chain.

- It helps businesses to capture and study a huge amount of data.

- The whole data is collected and visually displayed in the form of charts or graphs.

“The managers then use this data to plan and make decisions for the future of the business. But it is not this simple. Supply chain managers need to find very relevant data and sort it concisely. They can’t just gather and provide too much information to already overwhelming stakeholders.”

Key Note!

What is the Importance of Data Analysis in Supply Chains?

SC analytics is a powerful tool that can be used to identify inefficiencies in the supply chain and take action to address them. Building an analytics strategy requires organizations to consider the types of data they collect, the tools they use to analyze the data, and how they use the insights gained from the data to improve their supply chain.

“There are several ways to use supply chain analysis to improve supply chain operations and customer satisfaction. The best approach will depend on the organization’s objectives, data sources, and the volume and types of data.”

Key Note!

Supply Chain Planning Models:

A supply chain planning model is a depiction of the flow of goods through an entire supply chain. It’s a way of visualizing how a company will manage its inventory, the resources it will need to produce the goods, the transport and distribution systems involved, and more. Planning models are especially useful when trying to cut costs and improve efficiency. For example, they can help companies determine which suppliers they should partner with or which materials they should buy in bulk. In addition, they can help companies measure their progress and identify areas for improvement.

- Supply chain planning models are helpful for companies that have multiple locations or are looking to expand their supply chains.

- They allow managers to visualize how future business decisions will affect employees at all levels of the organization.

“A supply chain planning model can include any number of different components. For example, it could include a list of each item’s attributes (e.g., size, color, quantity), transportation routes from one location to another, storage locations and more.”

Key Note!

Supply Chain Analysis Tools:

With the help of chain analysis, you can see everything from the availability and price of raw materials, to transportation and logistics, final products, demand, and so on. In other words, the supply chain analysis tools won’t just help you understand how your supply chain works, but will also make you spot those companies which, whom you can do business with. For example, purchasing raw materials to create a new product or selling your products to new businesses. And the final result is the expansion of your company.

1. Descriptive Analysis:

This is the best type of supply chain management analysis that you can use to check out the past performance of the supply chain. It will tell you what has happened, so you can check if the results are matching with your plans and objectives. This method uses data mining to gather raw information from the supply chain. Summarizing it and presenting it in a compact form will allow you to get a clear image of the desired period in the past.

2. Predictive Analysis:

If you want to see what might happen in the future, this is the method you should use. As the name suggests, predictive analytics will form potential scenarios that may take place in a month, two, or a year from now. Although it is never guaranteed that they will happen exactly as predicted by this method. Even so, you will know what to expect, in a significant proportion, so you can adjust your plans accordingly.

- Predictive analysis is a type of supply chain analysis that involves the prediction of future business trends such as market demand, sales, exchange rates, and other important metrics of your business.

- For this type of analysis, the application of statistic modeling and analysis of historical data is used.

- Using it, the future trends are understood and formulated for the better growth of your business.

“Mathematical models are formulated and tested until they are capable of reliably forecasting the future. Predictive analysis isn’t the 100 percent true prediction of the future but it only tells you the probability that what’s likely to happen with your business based on the trends revealed by analyzing historical data”.

Key Note!

3. Prescriptive Analytics:

In case you want to see what could happen and get useful pieces of advice on what to do if future scenarios come to life. This method will help out. In other words, you will be advised what to do according to what the method predicts to happen in the future, based on the acquired data.

4. Performance Metrics:

This is one of the best supply chain analysis models when one of the best supply chain strategies is used and the chain itself is performing. Just do have in mind that there are several metrics and each of them provides a different type of information. So, you need to decide which metrics are most useful and relevant to your business, so you can keep an eye on those in particular.

5. Hybrid Performance Measurement:

This is a more complex form of chain analysis, as it utilizes several methods in the same framework so that the business owner can take the best decisions. Thus, a hierarchy of objectives is used, together with mathematical equations and simulations that should present. Hypothetically, what could be possible if certain conditions are met?

Success Stories – Using the Right Supply Chain Analytics Tools:

1. DHL:

DHL is a multinational logistics company that offers supply chain management services and software. In 2018, DHL hired a doctorate in logistics and supply chain management qualified professionals and partnered with blockchain company Riddle & Code to improve its supply chain and customer experience through blockchain technology. With this partnership, DHL will be able to track individual shipments in real-time.

2. SWEDISH RAILWAY:

In 2018, the Swedish Railway partnered with SAP to improve its ability to manage its global supply chain. The partnership has allowed the railway to optimize its procurement, logistics, and asset management.

3. E.ON:

E.ON is a global electricity and gas company. In 2018, the company partnered with SAP to better manage its global supply chain. Using data collected through its IoT platform, E.ON is able to improve energy management and customer service.

Supply Chain Planning Techniques:

Supply chain planning can be done through a variety of different techniques, including forecasting and optimization. By using supply chain planning techniques, businesses can optimize their inventory levels, reduce costs, and improve the overall efficiency of their operations.

1. Forecasting Technique:

One common method of supply chain planning is forecasting. In this technique, a business uses historical data to estimate future demand for its products or services. By doing this, businesses can predict how much inventory they will need to meet expected demand in the future.

2. Optimization Technique:

Another supply chain planning technique is optimization. In this technique, businesses use advanced algorithms to optimize their inventory levels based on past performance and customer demand patterns. By doing this, businesses can improve their overall efficiency and reduce costs.

The first step before applying a supply chain planning technique is to identify your objectives.

- What is the purpose of collecting supply chain data and analyzing it?

- What are you hoping to achieve?

- How will it help you to focus your efforts and identify the data that is most relevant?

Things to Do Before Applying a Supply Chain Technique:

In addition, organizations should consider the following before applying a technique:

1. DATA SOURCES:

Where are your data sources coming from? How can you ensure that the data is accurate and reliable?

2. DATA TYPES:

What types of data are important to your supply chain?

3. DATA AVAILABILITY:

Is the data available in a timely manner? Can it be accessed by all members of the supply chain team?

4. DATA OWNERSHIP:

Who is responsible for collecting and analyzing data? Who owns this data?

5. DATA SECURITY AND PRIVACY:

How is the data being secured? Are there any impactful compliance requirements?

6. DATA ANALYSIS CAPABILITIES:

- What tools are you using to analyze supply chain data?

- What types of reports and visualizations are you creating?

Transforming Supply Chains With Data Analytics and Intelligence:

The process of collecting data, analyzing it, and using it to make decisions that improve performance is known as supply chain analytics. The increased variety and volume of data available today provide an opportunity for businesses to identify inefficiencies in their supply chains and take action to address them. In order to turn data into analytics and intelligence, organizations must build a data-driven culture that embraces collaboration, uses the right tool like SCOR Model, and is compliant with privacy regulations. With the right approach and the right technologies, businesses can use data analytics and intelligence to transform their supply chains.

3 Tips to Improve Your Supply Chain Analysis Strategy:

The following are 3 tips to improve your SC Analytics strategy:

1. START SMALL:

It is important to prioritize projects that will have the greatest impact on the organization. Building a big data analytics project can be costly, time-consuming, and complex. Start small with a few projects that have a clear objective and that can be completed relatively quickly. This will help you to gain experience and show value quickly.

2. FOCUS ON DATA THAT MATTERS:

In order to be effective, supply chain analytics must be actionable. This means that the data must be accurate and must have a legitimate impact on the supply chain. While all data has value, only data that is truly relevant should be collected and analyzed.

3. BUILD A CULTURE OF COLLABORATION:

Supply chain analytics can provide value to organizations of all sizes and in a variety of supply chain environments. However, the best results are achieved when organizations create a collaborative culture where data is accessible to all members of the supply chain team.

Supply Chain Analysis Examples:

Several examples are demonstrating the use of SC Analytics to achieve organizational goals. For your better understanding, here is a brief explanation of three such examples:

1. Capacity Planning:

Capacity planning is made to match the manufacturing capacity to sales demand. Different analytical tools are used to make a mathematical model for your business. Then the whole data is analyzed to predict the future capacity of the sales.

2. Stimulation and Scenario Analysis:

Stimulation and Scenario analysis is an example of supply chain analytics which is used for strategic planning for determining the potential business scenarios. It will help to shape the company’s future and help your company standstill during numerous crises.

3. Sales & Operations Planning:

Sales and operation planning is used to look at the financial bottom line to determine the most profitable production. It is used to determine the sales scenario and maximize future production.

Final Thoughts:

With the help of supply chain analysis models, you will be able to take a closer look at how a supply chain evolves and performs. Of course, you need to find the best method that works in the case of your particular supply chain and not be afraid to adjust these methods. But only if you realize that the obtained results are not as detailed as expected. As you can see, there is a situation in which hybrid methods were utilized in order to take as many advantages as possible from several methods at the same time.

Supply chain analytics is the process of collecting data, analyzing it, and using it to make decisions that improve performance. The increased variety and volume of data available today provide an opportunity for businesses to identify inefficiencies in their supply chains and take action to address them. Supply Chain data analytics is a very important part of your business supply chain. It can effectively help you achieve your data organizational and future business goals.