What is the SCOR Model?

Supply Chain Operations Model or SCOR Model is the planning and diagnostic system of supply chain management. It is the product of the Supply-Chain Council (a global non-profit consortium) whose methodology, diagnostic, and benchmarking tools help organizations make dramatic and rapid improvements in supply chain processes. The SCOR model supply chain helps developers build distributed systems quickly, and it provides them with all the basic building blocks they need to get started. It is also used to evaluate and compare supply chain activities and performance. You can use it to build anything from a small single-machine application up to a large distributed application with thousands of machines across multiple data centers.

Understanding the SCOR Model Diagram:

The SCOR model diagram is a comprehensive framework used in supply chain management to analyze and improve supply chain performance. SCOR Model stands for Supply Chain Operations Reference model, and it serves as a tool for businesses to understand, map out, and optimize their supply chain processes. Martin Fowler created it to make it easier to build distributed systems that are reliable, resilient, and highly available.

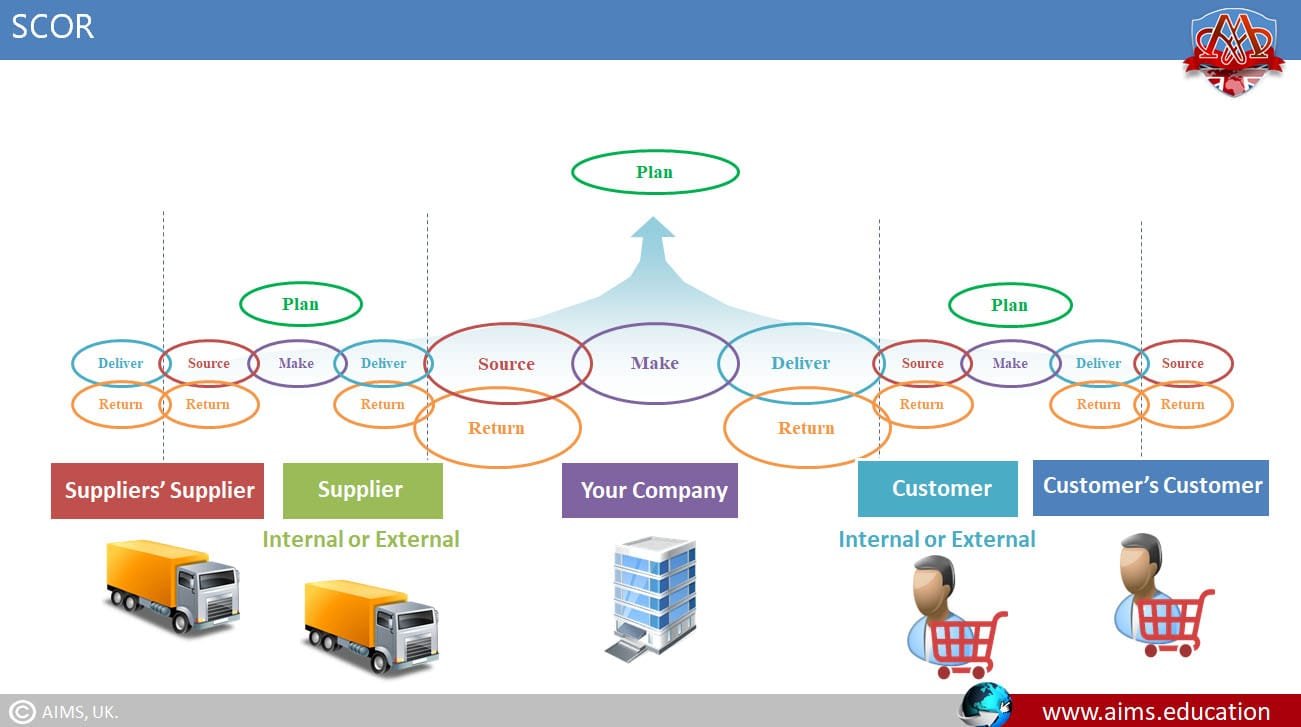

- The supply chain operations model breaks down the supply chain into six primary management processes: Plan, Source, Make, Deliver, Return, and Enable.

- Each of these processes is examined through five performance dimensions: Reliability, Responsiveness, Agility, Costs, and Asset Management Efficiency.

This structured approach facilitates the identification of areas for improvement, benchmarking against industry standards, and implementation of best practices in supply chain management.

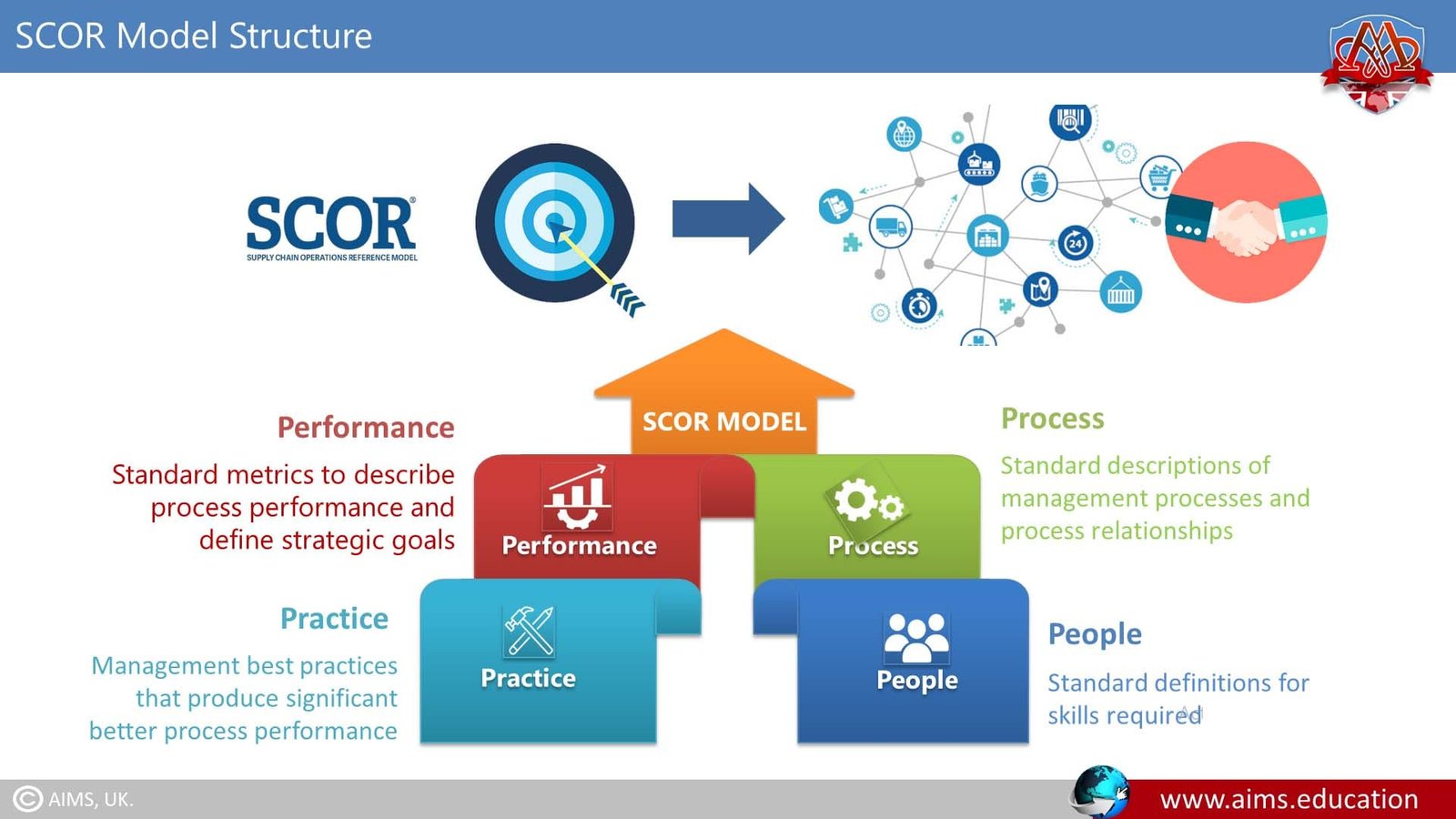

4 Elements of the Supply Chain Operations Model:

The SCOR Model is anchored on four key elements that interact closely to drive supply chain efficiency and effectiveness: Performance, Process, Practice, and People.

1. Performance:

This element is fundamental to the SCOR model, emphasizing the importance of measuring, managing, and improving key performance indicators (KPIs). These indicators span across the five performance dimensions of reliability, responsiveness, agility, costs, and asset management efficiency, allowing organizations to assess their supply chain operations comprehensively.

2. Process:

Processes are the backbone of the SCOR model supply chain, detailing the operational flow and activities required to meet supply chain objectives. The model provides a standardized process framework that spans plan, source, make, deliver, return, and enable, ensuring consistency and comparability across different supply chain setups.

3. Practice:

Practices refer to the actual methods, techniques, and tools applied within the supply chain processes to achieve desired performance outcomes. By adopting best practices, companies can optimize their operations, reduce costs, and improve service levels. The SCOR model serves as a repository of standardized best practices that can be adapted to various supply chain environments.

4. People:

Recognizing the critical role of human resources in supply chain management, the People element focuses on the skills, organization, and collaboration necessary to execute supply chain processes effectively. This includes the training, development, and empowerment of employees, as well as fostering a culture of continuous improvement and team collaboration.

Processes, Levels, and Limitations of the SCOR Model:

The SCOR has been developed to describe the business activities associated with all phases of satisfying a customer’s demand.

1. Primary Management Processes in the SCOR Model Supply Chain:

The SCOR Model itself contains several sections and is organized around the five primary management processes of Plan, Source, Make, Deliver, and Return. By describing supply chains using these process building blocks, the Model can be used to describe supply chains that are very simple or very complex using a common set of definitions. As a result, disparate industries can be linked to describe the depth and breadth of virtually any supply chain. The Model has been able to successfully describe and provide a basis for the improvement of supply chains and value chain management for global projects as well as site-specific projects.

- It spans all customer interactions (order entry through paid invoice), all physical material transactions (supplier’s supplier to customer’s customer, including equipment, supplies, spare parts, bulk product, software, etc.), and all market interactions (from the understanding of aggregate demand to the fulfillment of each order).

- It does not attempt to describe every business process or activity. Specifically, the SCOR Model supply chain does not address sales and marketing (demand generation), product development, research and development, and some elements of post-delivery customer support.

It should be noted that the scope of the SCOR supply chain model has changed and is anticipated to change based on Council member requirements. With the introduction of Return, the SCOR Model was extended into the area of post-delivery customer support (although it does not include all activities in that area).

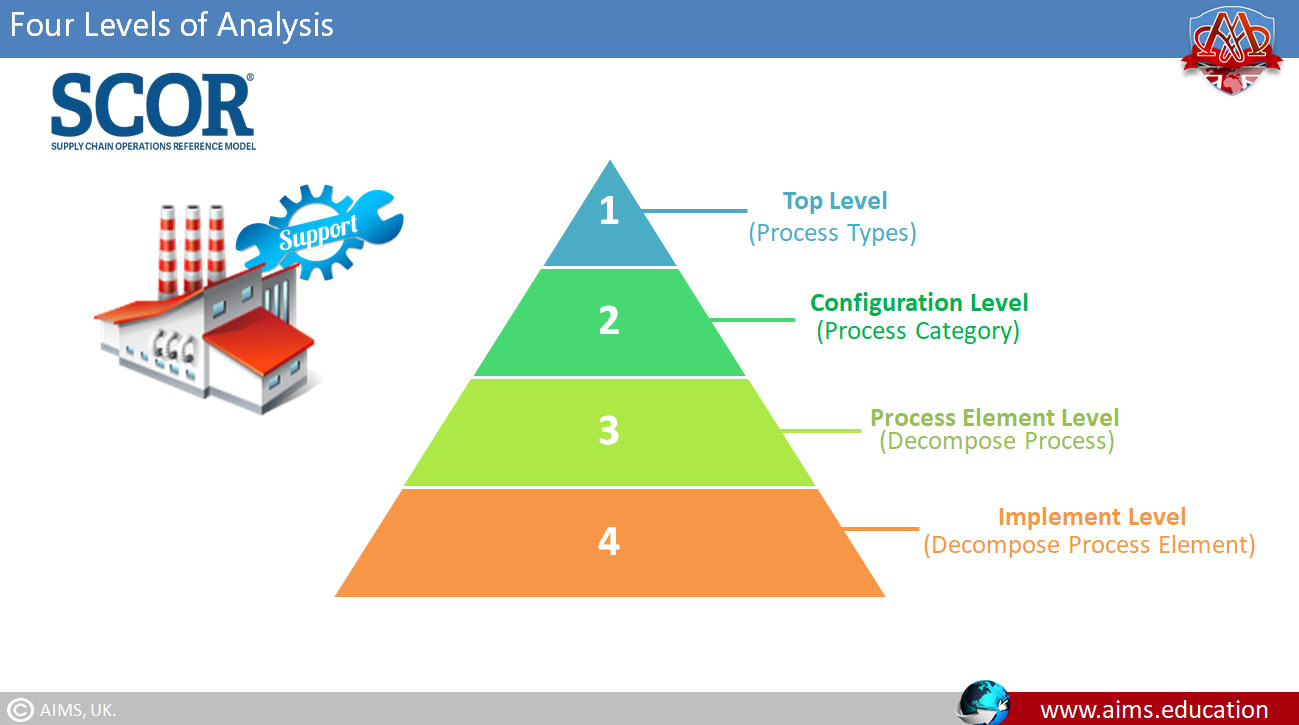

2. Levels in the Supply Chain Operations Model:

It is designed and maintained to support supply chains of various complexities and across multiple industries. The Council has focused on three process levels and does not attempt to prescribe how a particular organization should conduct its business or tailor its systems/information flow. Every organization that implements supply chain improvements using the Supply Chain Operations Model will need to extend the Model, at least to Level 4, using organization-specific processes, systems, and practices.

3. Limitations of Scope of the SCOR Model:

The SCOR model is silent in the areas of human resources, training, and quality assurance. Currently, it is the position of the Council that these horizontal activities are implicit in the SCOR model supply chain and other highly qualified organizations are chiefly concerned with how an organization should train, retain, organize, and conduct their quality programs. Just as the Council recognized the requirements for marketing and sales in commercial organizations, the Council is not minimizing the importance of these activities, but they are currently out of the scope of the supply chain SCOR model.

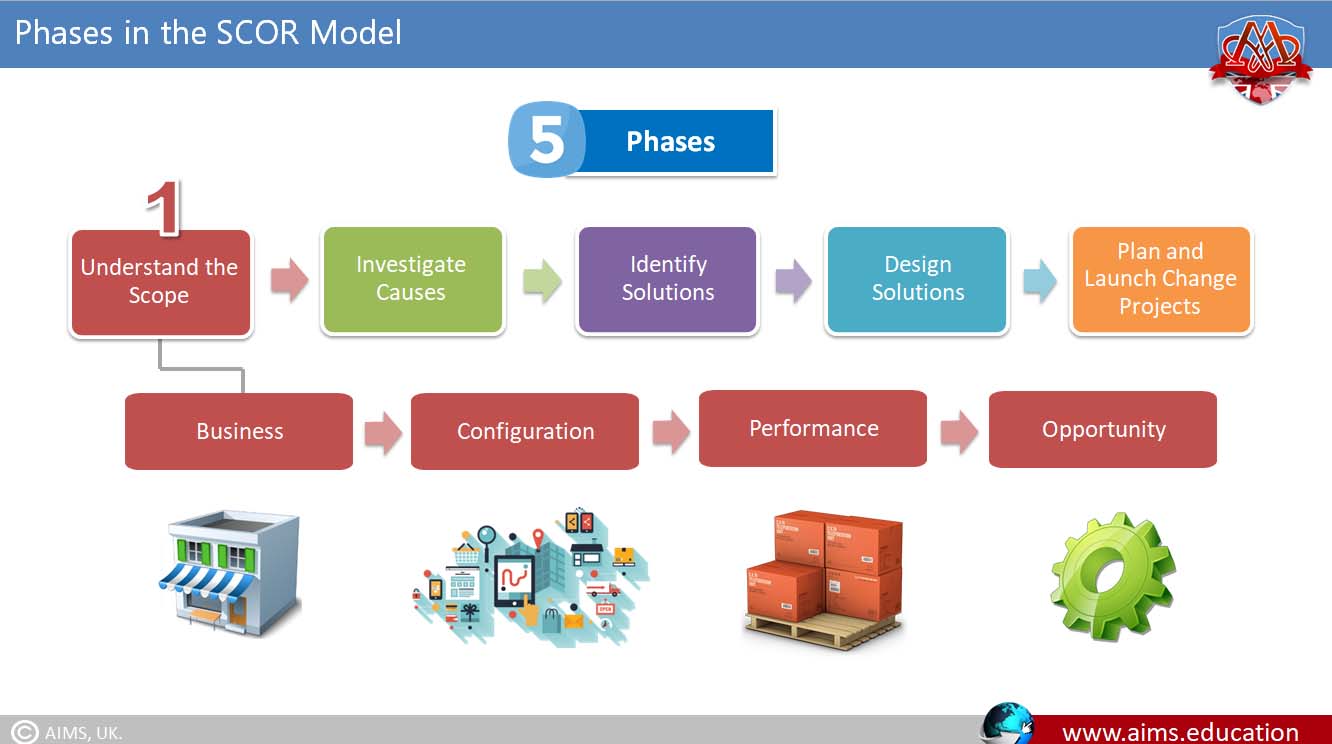

5 Phases in the SCOR Model:

Since the inception of the model companies have looked at how to best utilize the rich content of the Supply Chain Operations Model. Supply Chain Council has supported and continues to support practitioners by offering training focused on the interpretation and use of the Supply Chain Operations Reference Model. Experience tells us that the SCOR model as a tool needs to be integrated into existing project methodologies used, where they exist. Effective supply chain organizations have learned that using the SCOR Model supply chain is not a business goal; it is a tool to reach the true business goal: An integrated optimized supply chain, meets market requirements.

A typical Supply Chain Operations Reference project comprises the following phases:

Phase-1. Understand the Scope:

The scope of a Supply Chain Operations Reference Model project is defined by the following components:

A. BUSINESS:

Understanding the markets the supply chain serves, the products and/or services the supply chain delivers and the competitive landscape for each product and market.

B. CONFIGURATION:

Understanding the high-level processes: Develop geographic maps and thread diagrams to understand material flows and supporting processes.

C. PERFORMANCE:

Understanding the areas of underperformance: Companies develop scorecards and may organize a benchmark to understand how their supply chains perform in comparison to similar supply chains.

D. OPPORTUNITY:

Defining the improvement opportunity: Setting the scope of the effort. Focus on one or few supply chains and one or few metrics per supply chain.

Phase-2. Investigate Causes:

A. DETERMINE WHERE THE ROOT CAUSES ARE:

Metrics decomposition: For each problem metric identify the diagnostic metrics and collect the data to calculate these diagnostic metrics. Determine the problem metric or metrics. Repeat this process until no more diagnostic metrics can be identified;

B. PROCESS PROBLEM DISCOVERY:

For all diagnostic metrics, determine the associated processes. For each process collect information about how the process operates. (‘operates’ not ‘is supposed to operate’). Collect relevant information about who performs the work, sources or lack of relevant information to perform the work, rules, and regulations that apply, and tools and software supporting the process. Collect observed performance information from those who perform the work.

C. IDENTIFY THE PROBLEMS:

Group relevant observed process and performance problems together and determine how this impacts the overall problem. (Cause and Effect).

Phase-3: Identify Solutions:

Review different ways to solve the individual observed problems and the overall problem.

A. RESEARCH BETTER PRACTICES:

Determine how others have solved similar problems. Identify best practices, leading practices, and software and tools that may address individual problems and/or the overall problem;

B. DEVELOP WHAT-IF SCENARIOS:

Using information about alternative practices, new technology, internal knowledge, and external resources* describe new ways to configure and organize the processes. (*) External resources can be paid consultancies, peers in other industries, or peers in other business units in the same company. Internal resources and knowledge refer to workers in or close to the process. Some IT resources may qualify as internal resources;

C. REVIEW AND SELECT:

Review each scenario. Weigh improvement impact against estimated cost, risk, effort, lead time, and feasibility. Select the appropriate (or best) solution scenario for each problem. The collection of these solutions is the supply chain strategy to resolve the overall problem.

Phase-4 Design Solutions:

Document the new processes, technologies, and organizations. Describe the to-be state.

A. DOCUMENT PROCESSES:

- Develop detailed transactional information.

- Develop detailed process flows and descriptions.

- Document how the process is organized, who does what, and what information is used and created in each process step.

- Develop detailed work instructions.

- Document how the work is done. Develop Standard Operating Procedures (SOPs) for new processes. Update SOPs for all processes impacted by the change.

B. DOCUMENT ORGANIZATIONAL DESIGNS:

- Develop detailed job descriptions.

- Document authority, responsibility, and span of control.

- Document training needs, and develop training if needed.

- Document metrics, and describe how the processes (and process owners) will be measured upon implementation of the new process.

C. DOCUMENT TECHNOLOGY REQUIREMENTS:

Describe how existing and/or new technology will support the new process. A business requirements document will enable internal and/or external technology providers to match their tools to the process needs. Solution design may require significant resources and time for projects with large dependencies on technology and may be considered separate IT projects.

D. DOCUMENT TRANSITIONS:

Describe the dependencies and restrictions related to the change. Estimate resource needs.

Phase-5: Plan and Launch Change Projects:

Create a roadmap to implement the changes.

A. DEFINE PROJECTS:

Define unique projects for implementation. Combine changes that impact the same technology, organizations, products, and processes as required. Note: Not all projects are equal: Large scope changes need managed projects, and small changes may need a memo to a manager with documentation.

B. CRITICAL PATH AND DEPENDENCIES:

Document the interdependencies of projects. “Project D requires Project K to be completed”. “Project F can start at any time”.

C. MANAGE THE PROJECT PORTFOLIOS:

Prioritize projects based on expected return, business strategy, and other relevant projects. Allocate resources; people, funds, and time.

D. LAUNCH AND OVERSEE THE PROJECTS:

Make sure the project deliverables result in the desired change.

Role of the Supply Chain Council:

The SCC was organized in 1996 and initially included 69 practitioner companies meeting in an informal consortium. Subsequently, the companies of the Council elected to form an independent not-for-profit trade association. The majority of the SCC’s members are practitioners and represent a broad cross-section of industries, including manufacturers, distributors, and retailers. Equally important to the Council and the advancement of the SCOR Model supply chain are the technology suppliers and implementers, the academicians, and the government organizations that participate in Council activities and the development and maintenance of the Model.

1. The Council Members:

At the time of this release, the Council has approximately 800 corporate members worldwide and has established international chapters in Australia/New Zealand, Latin America, Greater China, Europe, Japan, Southeast Asia, and Southern Africa with additional requests for regional chapters pending.

The Supply-Chain Council is interested in providing the widest possible dissemination of the Supply Chain Operations Model. The widespread use of the Model results in better customer-supplier relationships, software systems that can better support members through the use of common measurements and terms, and the ability to rapidly recognize and adopt best practices no matter where they originate. SCC requests that all who use the SCOR Model provide attribution to the Supply-Chain Council.

2. End-to-End Supply Chain:

This introduction is provided to assist new users of the SCOR supply chain model to begin analytic and implementation projects. It is intended to remind experienced users of the framework and structure of the Model when tackling more complex applications of the Model for their businesses. Finally, it is provided to orient members to the changes between Version 9.0 and Version 10.0.

Version 10.0 of the Supply Chain Model is the twelfth revision since the SCOR Model’s introduction in 1996. Revisions of the SCOR Model supply chain are made when it is determined by Council members that changes should be made to facilitate the use of the Model in practice.

Summary:

The Supply Chain Council acknowledges the diversity in Supply Chain Operations Reference Model projects, emphasizing that not all projects demand the exhaustive execution of listed detailed activities for successful outcomes. For example, supply chains with previously set realistic improvement goals may not need to re-engage in benchmarking exercises. Similarly, projects that don’t necessitate updates to software systems should avoid dedicating extensive periods to technology requirements documentation. This perspective is vital for professionals with an accredited MBA in supply chain management or supply chain management online diploma, as it encourages focusing efforts where they are most impactful and avoiding unnecessary redundancies in project execution.